CAR INTERIOR CUSTOM

Types of Customization

How It Works?

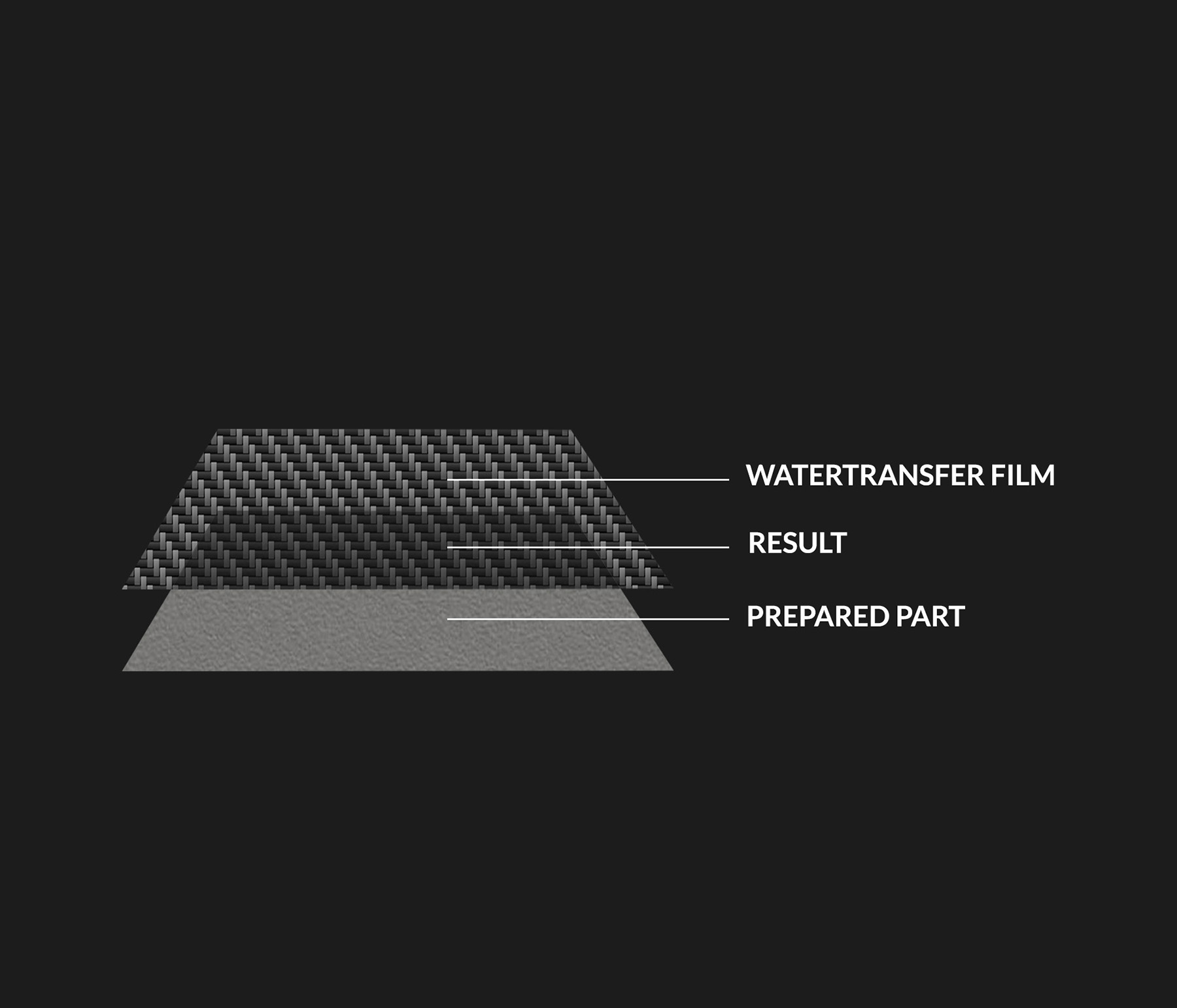

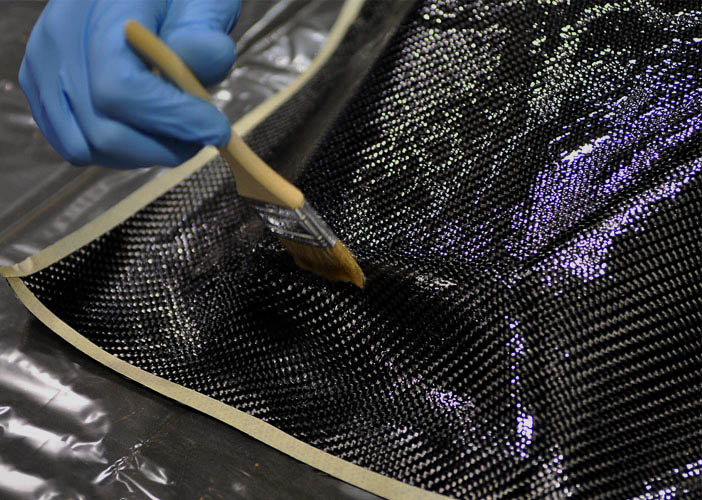

Hydrographic printing, also known as water transfer printing, follows a process similar to traditional painting — but with an added twist: a stunning texture layer.

Step-by-Step Process:

1. Surface Prep – cleaning and priming the part

2. Base Coating – applying the foundation color

3. Texture Transfer – using a special water-soluble film

4. Clear Coating – for protection and gloss

5. Polishing – final detailing and shine

No Film Left Behind

The texture film is printed on a water-soluble carrier. During the process, the film fully dissolves, leaving only a clean, flawless texture — no edges, no residue, just pure design.

Hundreds of Textures. Endless Possibilities.

From carbon fiber and brushed metal to exotic woods and stone — we have it all.

PORTFOLIO

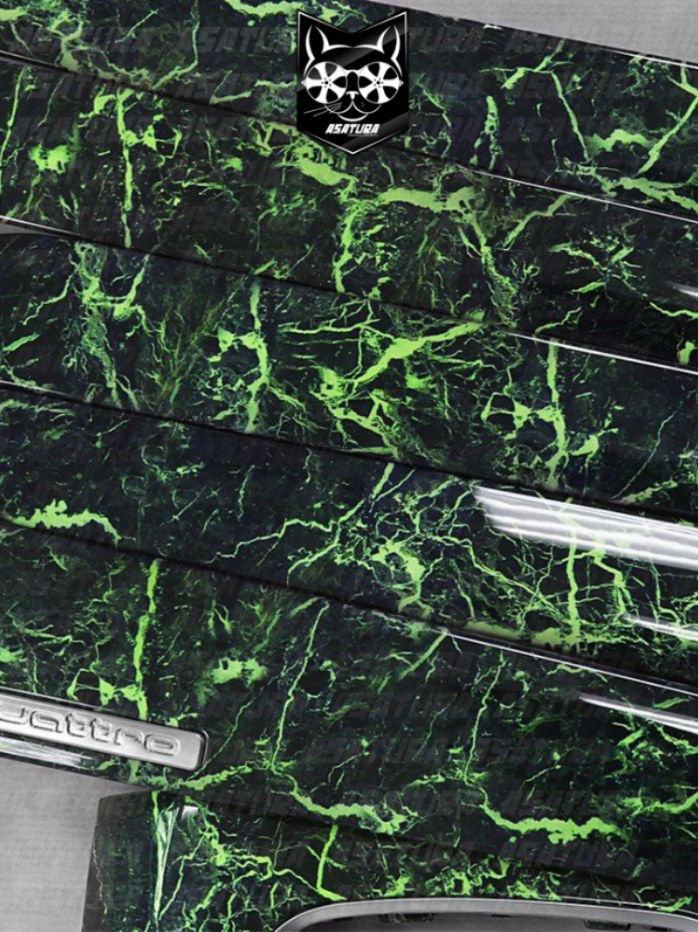

A WIDE RANGE OF TEXTURES

Wood

Metal

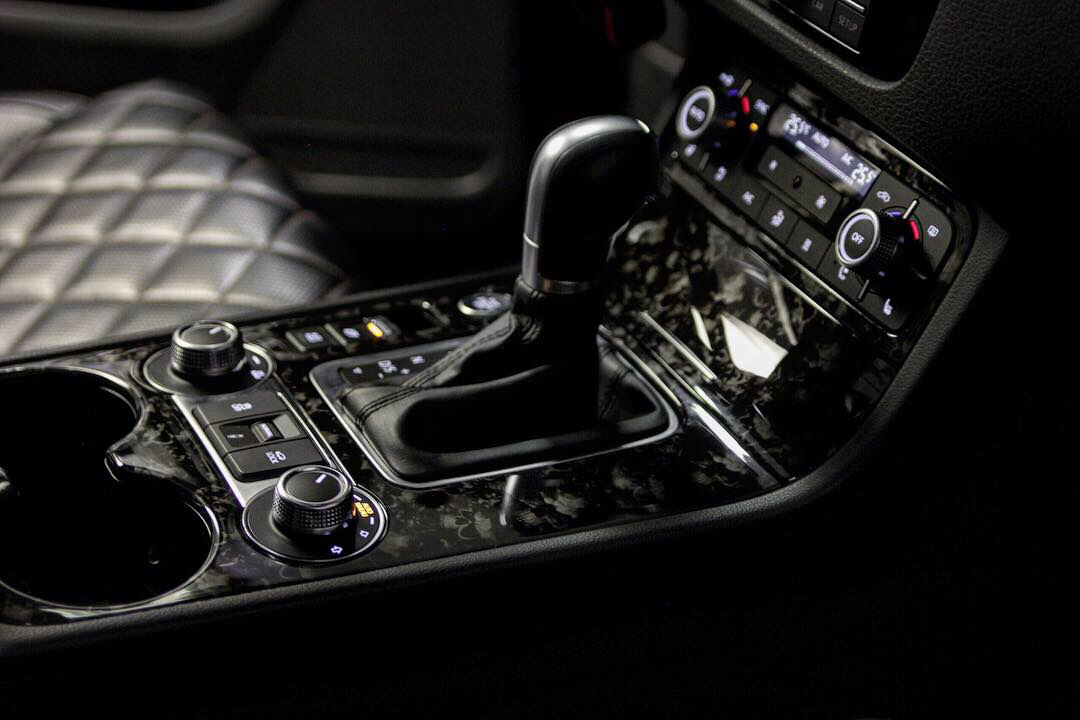

Carbon

Stone

Skulls

Abstraction & Graphics

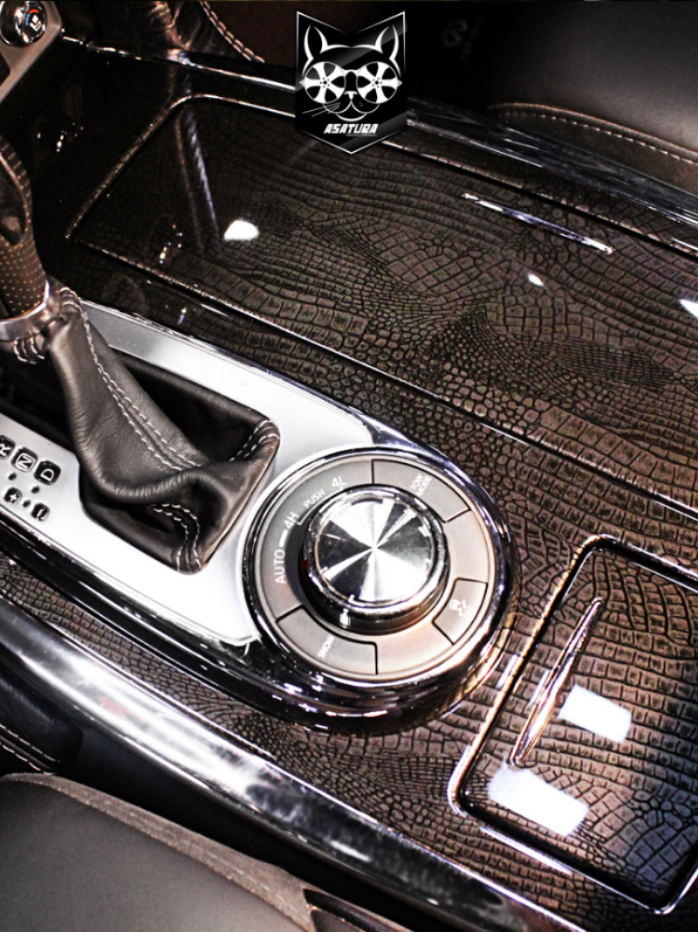

Skins

Camouflage

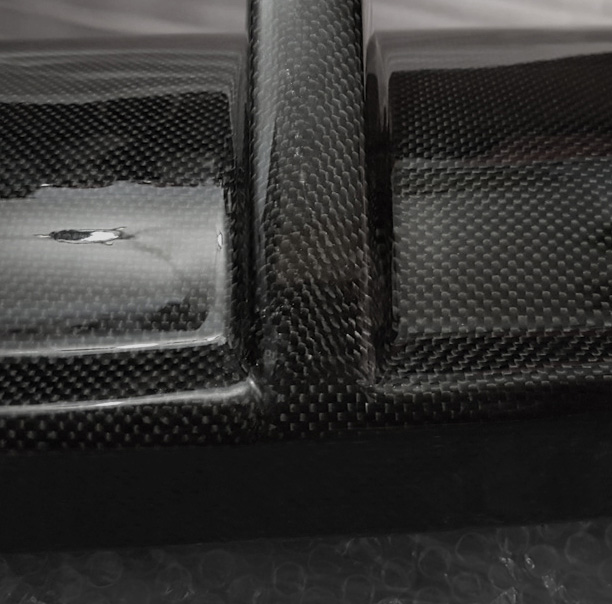

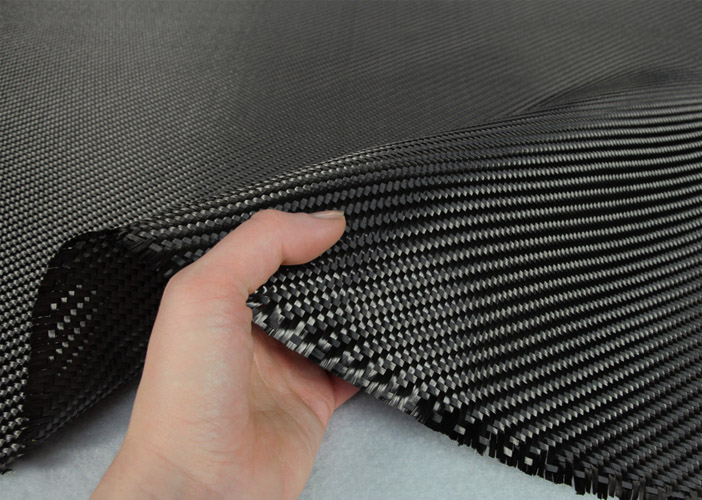

Carbon fiber is a composite material made from carbon filaments. Originally developed for motorsports and aerospace technology, carbon fiber gained widespread use due to its exceptional performance characteristics, such as light weight and high strength. Carbon fiber, or carbon-reinforced plastic, is known for its high strength, wear resistance, rigidity, and low weight compared to steel. In addition to its technical properties, high-quality carbon fiber has an attractive appearance that can change color and shade when exposed to direct sunlight.

Carbon fiber lamination is a process of enhancing parts to achieve a visually improved finish.

As a result, this process is most commonly applied to interior components (such as trims, handles, panels, inserts, and steering wheels) as well as exterior parts (like moldings, door handles, splitters, and spoilers).

Tactile detailing of interior or exterior elements means more than just a look — it’s about texture that feels real.

We recreate surfaces with near-photographic precision: from the brushed grain of natural wood, to the subtle roughness of carbon fiber or stone. Every texture is crafted to look and feel authentic, giving your vehicle a whole new sensory dimension.

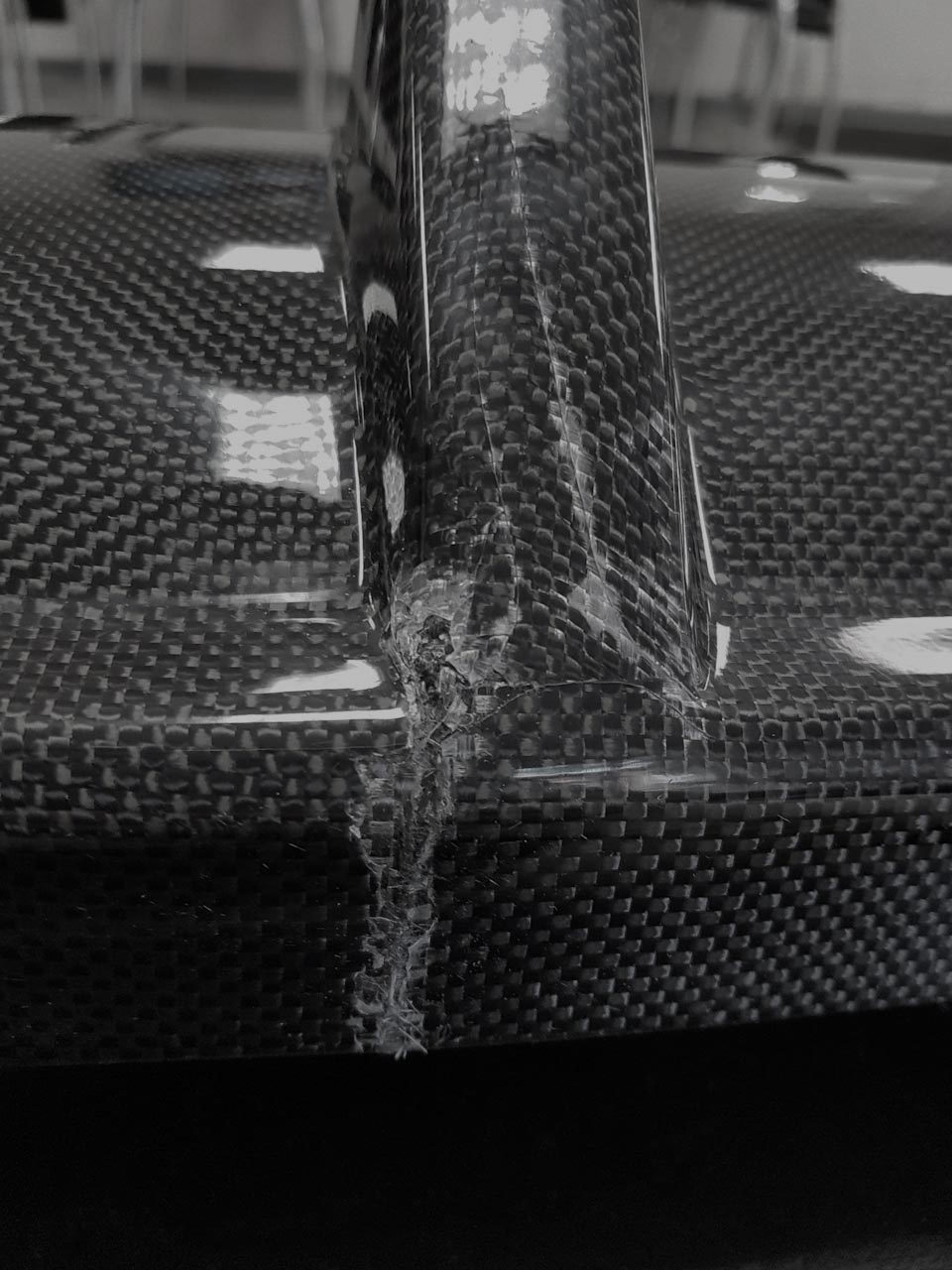

Every car interior has a lifespan. Over time, you may begin to notice scratches, cracks, mechanical damage, and other signs of wear on your panels.

The buttons on the dashboard and steering wheel start to wear down. Unfortunately, there are no products that can prevent this kind of damage. We offer a restoration service for your vehicle’s interior.

You can restore the original beauty of your car’s interior, and the new coating, made from high-quality materials, will last for many more years.

We restore materials such as plastic, natural wood, carbon fiber, and more.

Our main highlight is the ability to personalize your car’s interior. We can bring all your fantasies to life. If you’re unsure about something, we will help you make the right choice or create a unique design from scratch. From minimalism to extravagance, we can do it all.

We can also apply any finish to your interior design elements. With our many years of experience, we are capable of fulfilling any of your design dreams.

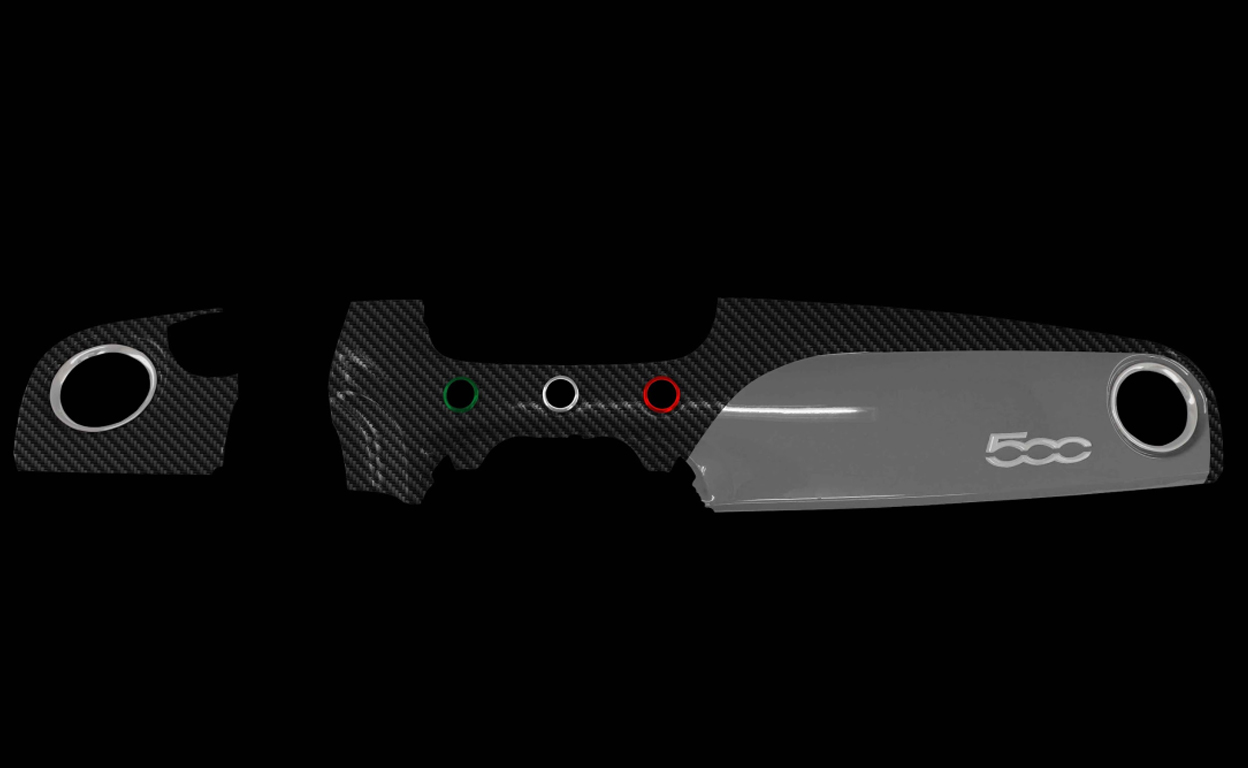

Before applying the hydrographic finish, we offer a computer visualization service — a key step that helps you see exactly how your part will look after the transformation.

Why It Matters:

Accurate Preview – get a high-quality, detailed render that reflects all your preferences and the part’s actual shape and size.

Smart Revisions – make adjustments before the work starts saving both time and budget.

Confidence Guaranteed – you’ll know exactly what to expect, with no surprises at the end.

With our 3D visualization, you can confidently approve the design and feel great about your choice — before we even touch the part.

To calculate the cost of the work for your vehicle, please contact us!